“Well it all depends on the individual requirements of the project.” Carol Sebert, President of Creative Matters said in response to my question regarding how to choose the right quality of rug or carpet. “As you know we do a considerable volume of work in hospitality and contract which has its own set of requirements outside of simply the aesthetic.

Flame resistance, durability, and cleanability are all factors we have to consider when working with our clients. Add in the advances in technology over the past decade or so and we are able to offer fully customized solutions for our clients that best meet their needs.”

Creative Matters is a Toronto, Canada based firm which specializes in custom rug, carpet, and broadloom (not to mention wallcovering) design and production solutions for a diverse selection of hospitality, contract, and government clientele the world over. The firm is also known widely in the handmade rug market for their signature collections that are generally distributed through private label type arrangements with retailers. The staff of Creative Matters, which numbers around a dozen women, are an enthusiastic group with diverse backgrounds who share a strong collaborative work ethic that is outcome driven. “Well you’ve seen how it works.” begins Sebert in reference to my visit with the firm last November for one of their Art Days, “We get the entire staff together to simply create with no predetermined outcome other than a library of work to build upon for our own collections as well as for clients.”

It is this oeuvre of work that the designers of Creative Matters utilize when working on projects for clients. “If we are working with a boutique hotel for instance, we have to take into account all of the various spaces: halls, stairwells, suites, lobbies, etcetera.” says Sebert. Depending on the caliber of the hotel, the budget, the planned life of the interior—three to five years for an upmarket boutique hotel, perhaps seven or more for something more middle market—the firm begins designing carpets balancing cost, function, and the technique of construction.

“Oh wouldn’t if be great if everything could be handmade?” Sebert says rhetorically, “But the realities are that certain constructions and materials are simply better for different applications.” Woven Axminster or dye injected broadloom are often used in hallways for example with Axminster being the more expensive of the two options. “Dye injected carpets are usually nylon because using wool would make the pricing more or less comparable to Axminster.” The real advantage of injected though is from a design standpoint. “We have made these stunning large scale, no repeat patterns for hotel hallways. It’s something we cannot achieve with any other construction and clients love the results.” The firm also works in Wilton construction though it has limitations. “It’s only four color, in cut or loop pile, but it has design restrictions and is rather expensive compared to other methods.” Sebert also laments slightly the drawbacks of Wilton noting it is a very stable, beautiful, and solid method of carpet construction.

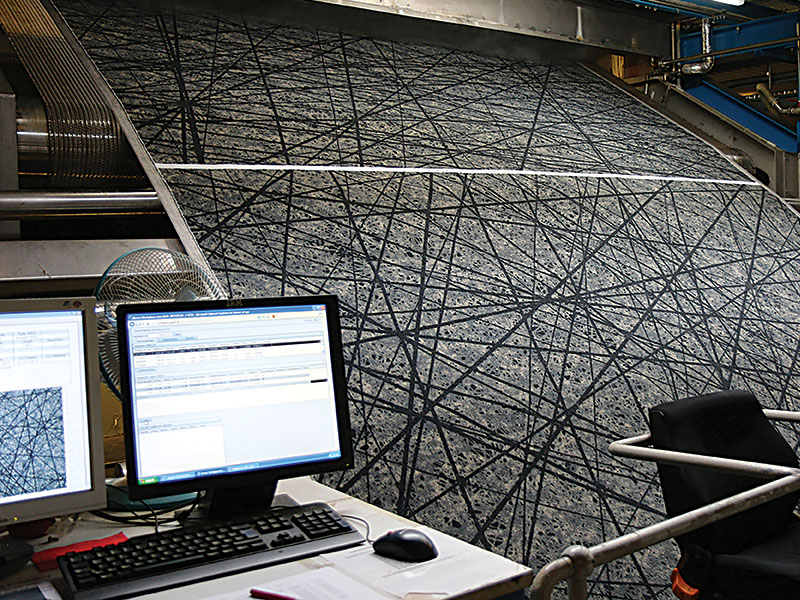

Tufted carpets offer a performance advantage over that of handmade carpets in high traffic environments making them perfectly suited for interiors where a high degree of artistic design expression is required along with durability. Shown here is the MacDonald Room rug in Canada House, London, UK based on original artwork by Sean William Randall and realized by Creative Matters.

“Now in a hotel suite is where we get to be a little more explorative with construction.” While the aforementioned Axminster and printed carpets are used in suites—either installed wall-to-wall, as a fitted rug, or inset to avoid tripping hazards—hand-tufted and hand-knotted are often used when an area rug is specified. “Tufted is certainly the better option for wear.” Sebert states emphatically, noting they are often used in lobbies and reception spaces, “But we use handknotted in areas with low traffic demands and in residential of course.” Both techniques offer one advantage the others cannot yet compete with: ultimate design flexibility. “We can do anything austhetically in tufted or handmade, but this comes back to our expertise in adapting our design ideas to the construction.”

Hand-tufted and especially hand-knotted offer a “sky’s the limit” approach to design, but due to flame resistant requirements in hospitality they might not always be suitable because of material. Wilton has repeat and color restrictions and is more expensive, but is also “just beautiful.” Axminster’s color blending is “stippled” which depending on the design may or may not be appropriate. “Printed carpets are very interesting though.” Sebert enthusiastically states “There are a variety of substrates onto which the designs are printed.” Each of these substrates has a different textural pattern combining loop and cut pile in various iterations. “Designing to a substrate can create very interesting effects.” and it is something the team at Creative Matters takes into account when working with their clients. Sebert again, “What it really comes down to is is understanding and balancing all of the requirements for the project.”

Sebert readily expands on this with an overwhelming barrage of additional technical concerns including but not limited to: material blends to increase performance, producing multiple identical carpets allowing carpets to be swapped for cleaning, determining the best mill to use in order to minimize waste—which includes global sourcing as most North American mills produce 12' (3.65m) wide goods whereas European mills produce 4m (13.1') wide goods with Asian mills often producing both widths, factoring delivery times, selecting the right construction taking into account the cost of minimum quantities, so on and so forth until one realization becomes apparent: When dealing with requirements outside that of the average residential consumer, significant and broad technical product knowledge is required.

Images courtesy of Creative Matters and Ege